Solutions Through Chemistry

Secured by G-Tape™

Hand Tearable

Highly Weather Resistant & Water Proof

Residue Free Removal & High Tensile Strength

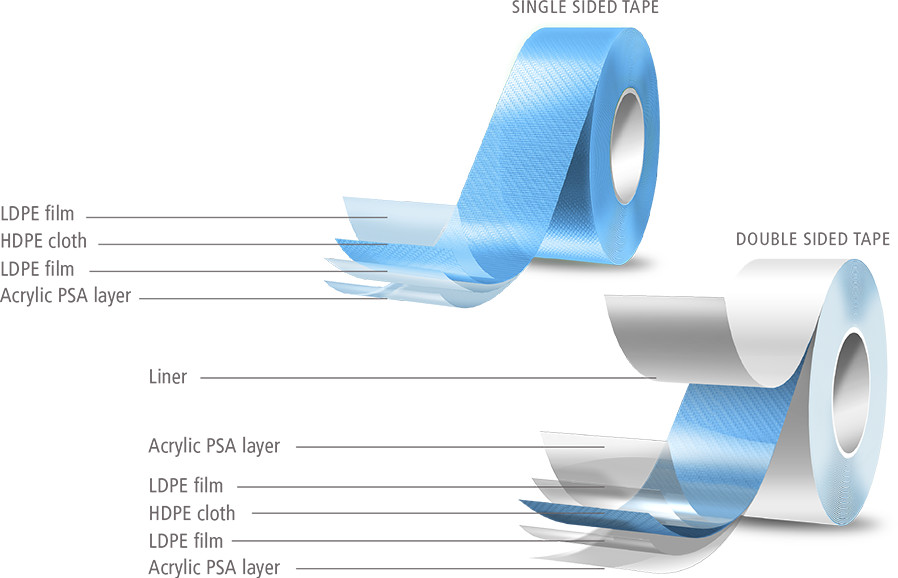

Pressure sensitive adhesive (PSA) tapes are made up of two basic layers, the backing substrate and the adhesive. Most products on the market today use rubber or butyl based adhesive structures and simple substrate.

Mitsubishi Chemical G-Tape™ sets itself apart from the industry with our patented acrylic adhesive and woven cloth substrate. The acrylic adhesive not only provides high adhesion strength, but is also repositionable without leaving a sticky residue. Even when the adhesive is modified for permanent bonding applications, it is still repositionable for approximately the first hour after activating the adhesive.

The way the cloth substrate is woven means that G-Tape is straight line hand tearable, every time. Additionally because it is cloth, regardless of how G-Tape is torn, it will not create rough, sharp edges.

Stability and strength are then added with a low density polyethylene film. The film increases the tensile strength and abrasion resistance of G-Tape.

This combination of key features makes Mitsubishi Chemical G-Tape™ an ideal product across many different applications including automotive, aviation and building/construction.

Usages

Automotive

Mitsubishi Chemical G-Tape™ is a hand tearable, residue free and high weather resistant tape. These features offer many solutions to automotive industry and after markets.

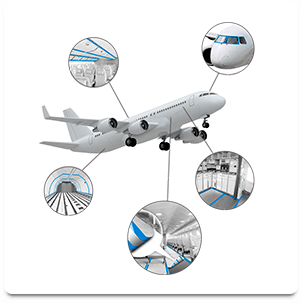

Aviation

Mitsubishi Chemical G-Tape™ offers flame retardant feature for many applications in the aerospace industry. Since G-Tape does not leave residue on floors and surfaces, it makes maintenance operation easier.

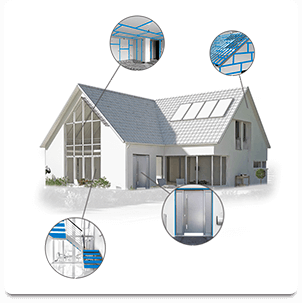

Building & Construction

Mitsubishi Chemical G-Tape™ is a highly weather resistant, hand tearable and water proof tape. These features improve productivity and quality in the building and construction industry.

Performance

Representative Grades of Mitsubishi Chemical G-Tape™| Masking & Protection | Waterproof & Airtight | Double Sided | HVAC | |||||

|---|---|---|---|---|---|---|---|---|

| 1006 | 1008 | 1009 | 3030 | 3040 | 9030 | 2010 | ||

| Thickness | 0.16 | 0.16 | 0.16 | 0.17 | 0.22 | 0.22 | 0 | mm |

| Adhesion Strength | 6 | 8 | 9 | 30 | 40 | 30 | 0 | N/25mm |

| Holding Power* | 0.1 | 0.1 | 0.1 | 0.2 | 0.9 | 0.6 | 0 | mm |

| Tensile Strength | 280 | 350 | 280 | 380 | 400 | 400 | 0 | N/50mm |

| Elongation | 15 | 17 | 15 | 16 | 21 | 21 | 0 | % |